Gaffa Razak

Turbo-Generator Specialist (Freelancing Services)

Gaffa Razak

Experienced & Certified Technical Field Advisor – Turbo-Generator | Generator Maintenance, Overhauling, Repair & Rewind (Steam & Gas Turbine) | IEEE Member

Phone:

+6019 308 6 382

Email:

Address:

No 13, Jalan Ecohill 7/6B

Setia Ecohill 2,

43500 Semenyih,

Selangor,

MALAYSIA

Date of Birth:

June 28, 1983

Welcome to Gaffa Razak's Portfolio

As a Consultant and Technical Advisor for Turbo-Generators, I leverage over 20 years of hands-on experience and global certifications in generator maintenance, overhauling, repair, and rewinding to deliver high-quality service and strategic support for power plant projects worldwide.

I have worked extensively with OOEM machines from ALSTOM, John Brown, Toshiba, Siemens, Mitsubishi, NEI-Parsons, Ansaldo Energia, ABB Sae Sadelmi, and Brush—resolving complex issues and ensuring peak performance in both steam and gas turbine generators.

My journey began as a mechanical semi-skilled fitter and evolved into a certified field engineer role specializing in generator erection for WX/WY ALSTOM Turbo-Generators. Since then, I have led and supervised numerous turbo-generator projects across Southeast Asia and beyond, working with diverse technical teams and adapting quickly to challenging environments.

I am a proud member of IEEE (Institute of Electrical and Electronics Engineers), actively staying engaged with global engineering standards and best practices in electrical rotating machinery. My membership strengthens my technical credibility and ensures my work aligns with the most current advancements in generator technologies.

My mission is simple: to deliver reliable, efficient, and safe solutions that extend asset life and ensure power generation continuity—especially for aging fleets where experience matters most.

WORK EXPERIENCES

Mar 2024 - Current

Technical Advisor - Generator Specialist

(Mechanical, Rewinding, Repair)

GI ENERGY RESOURCES (Malaysia)

As a Technical Advisor - Generator Specialist at GI Energy Resources (Malaysia), my primary role involves providing support for all aspects of turbine and gas turbine generator equipment. This includes overseeing the installation process, preparing detailed Field Service Reports, performing maintenance, and diagnosing any issues with the equipment. I maintain open with clients and stay updated on the latest developments in generator technology. Additionally, I engage in freelance work for various clients, including GE, Nomac, Frontken (Philippines), and Aboitiz Power (Philippines), with the goal of building strong client relationships and delivering outstanding service and support.

Jun 2022 - Feb 2024

Lead Field Service and Technical Advising - Generator Specialist

GE VERNOVA (Steam Power)

As a Lead Field Service and Technical Advisor - Generator Specialist at General Electric Steam Power, my main responsibility lies ni providing technical assistance concerning all aspects of steam turbine generator equipment. My job entails overseeing the installation process, preparing detailed Field Service Reports, conducting routine maintenance, and troubleshooting any malfunctions related to steam turbine generator equipment. Additionally, I am responsible for conducting training sessions, communicating with clients, and staying informed about the latest advancements ni generator technology. My overall objective is ot cultivate strong client relationships and provide exceptional service and support.

Nov 2017 - May 2022

Lead TFA - Generator Specialist

FIELDCORE

-

Erection schedules, documents and procedures within faculty and assignment.

-

Expertise and experience, to ensure performance complies with equipment/system specifications.

-

Prepare erection work with necessary tools and consumables.

-

Report any non-compliance within faculty to superior.

-

Assure all the work complies with EHS requirement.

-

Implement any technical issue associated with GE supplied equipment.

-

Provide technical direction to skilled labor performing work on customer sites to assure the executed work reflects the technical requirements and quality standards of the sold product.

Oct 2015 - Nov 2017

Technical Field Service Manager

GENERAL ELECTRIC

Provide on site technical direction on Generator Inspection, repair and installation, commissioning and maintenance on customer owned power generation and industrial facilities (Power generation includes customer owned utilities, marine drives, industrial power plants and nuclear power plants utilizing gas and steam turbines; Industrial facilities include power generation, marine, petrochemical, paper, steel, automotive and transportation industries)

-

Perform maintenance, repair, and/or rebuild on both GE and non-GE turbine generator equipment.

-

Prepare and execute job-planning documents that define in detail the operations to be performed through engineering instructions, drawings, and process instructions.

-

Liaise effectively with customers in job planning, execution, follow up and sales support.

-

Provide technical direction to skilled labor performing work on customer sites to assure the executed work reflects the technical requirements and quality standards of the sold product.

-

Knowledge of GE generators with ability to provide routine maintenance checkout, repair and rebuild for wide range of equipment vintages.

-

Provide both external and internal timely and accurate professional reports.

-

Act as primary technical resource and assist in resolving engineering issues.

May 2010 - Oct 2015

Lead Field Engineer - Generator Erection

ALSTOM POWER ASIA PASIFIC

Execute work and/or direct local erection staff for technical correctness of erection activities in compliance with instructions. All work must be performed according to Quality, Schedule, Environmental and Health & Safety requirements. Job beriefing at home base according project requirements. Executes erection works, directs and/or supervises local erection staff in regard to:

-

Erection schedules, documents and procedures within faculty and assignment.

-

Expertise and experience, to ensure performance complies with equipment/system specifications.

-

Prepare erection work with necessary tools and consumables.

-

Report any non-compliance within faculty to superior.

-

Assure that equipment, instruments and tools are handled with care.

-

System walk down and handovers within requirements.

-

Implement any technical issue associated with ALSTOM supplied equipment.

-

Inspection of carried out work and handover equipment within requirements.

-

Coordinates with the superior on status of work. Keeps daily log book with all relevant information regarding non compliances, work task, improvements, delays, working time etc. Assures work are proceeded in compliance to the management systems. Assures Field Services, project and site regulations are obeyed.

Apr 2008 - Apr 2010

Generator Winding Specialist

ALSTOM POWER ASIA PASIFIC

As a Generator Winding Specialist at ALSTOM, my primary responsibility is to provide technical and winding erection support worldwide. With my extensive experience in generator winding systems, I specialize in hands-on generator winding structure and repairs. My work requires close collaboration with cross-functional teams to ensure that generator equipment installation, maintenance, and troubleshooting are handled seamlessly. Drawing from my field experience, I am well-equipped to identify and resolve issues efficiently, resulting in optimal performance and customer satisfaction.

May 2006 - Mar 2008

Field Technician - Generator

TNB REMACO

At TNB REMACO, I hold the position of Generator Technician, where my main responsibility is to provide technical assistance for all TNB assets. My expertise lies in mechanical work, specifically in the removal of generator rotors and servicing of these machines. This enables me to effectively collaborate with OEMs like ALSTOM, GE, MITSUBISHI, and TOSHIBA. My work involves close collaboration with cross-functional teams to ensure that equipment installation, maintenance, and troubleshooting are executed with precision. With my field experience, I can efficiently identify and resolve issues, resulting in optimal performance and increased customer satisfaction.

Aug 2019

Fast Stator Rewind - Supervisory Level

GE Learning Centre

Belfort, France

I finished an immersive technical training program on rapid stator rewind at the GE learning center in Belfort, France. The training focused on on-site stator rewind management, material planning, and outage preparation. Practical exercises enhanced skills, while interacting with industry experts enhanced the learning process. Emphasis was placed on safety and accuracy for dependable stator rewinding. Additionally, the experience involved a factory tour to observe the stator manufacturing process up close.

May 2014

Certification of Generator Technical Advisor for Conducting Inspection and Overhaul in Topair WX/WY Generator

ALSTOM Power Plant Training Centre

Birr, Switzerland

I am succesfully completed the type specific training and certification program and meets all requirements to execute, supervise, direct or provide technical advice for erection, inspection and overhaul work on ALSTOM's Air Cooled Turbo Generator type WY/WX.

Aug 2011 - Sept 2011

WX/WY Generator Retaining RIng Course

ALSTOM Power Plant Training Centre

I completed technical training on retaining rings at the ALSTOM center in Switzerland. The program covered practical skills and theoretical knowledge on installing and removing retaining rings. The curriculum included understanding applications, material properties, stress distribution, and failure analysis. The well-equipped training facilities and collaborative environment enriched the learning experience.

EDUCATION

PROJECTS & COLLABORATIONS

TECHNICAL SKILLS

Generator Overhauls (Minor & Major) ALSTOM WX/WY Air-Cooled WX14L WX16L WX18L WX18Z WX21L WX21Z WX23Z WY14L WY16L WY16Z WY18L WY18Z WY21L WY21Z WY23Z WY23Z (Single Shaft) WY25R

Generator Overhauls (Minor & Major) ALSTOM Topgas & Gigatop H2-Cooled WT18H WT20H WT21H WT21H (single-shaft) WT23E WT25E

Stator & Field (Rotor) Rewind Rapid Rotor Rewind for Topack Stator Rewind for Topack, Topair and Topgas

Generator Overhauls (Minor & Major) ALSTOM Topack Air-Cooled T180-180 T190-200 T190-240 T214-234 T214-269 T237-268 T240-370 T278-371

Retaining Ring Removal & Assembly All ALSTOM unit including Topair, Topack Topgas & Gigatop

Repairs and Modifications Stator Air Chamber Seal Replacement Stator Phase Seperator Refurbishment Stator Rewedging Resin Injection at Stator (DVV)

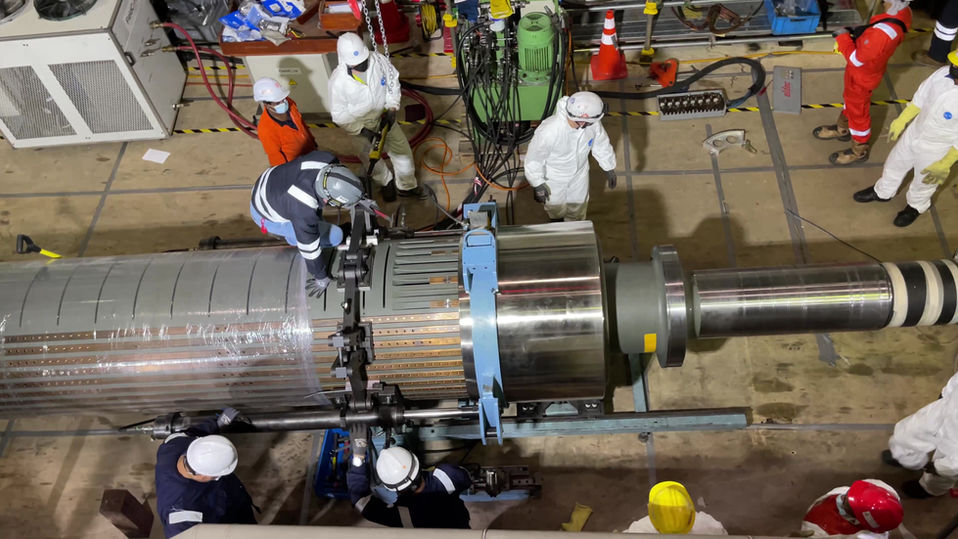

Gallery

A Visual Journey of Work Experience

REFERENCE & FEEDBACK

Ir Ts Azmi Mohd Shahit

Electrical Engineer at TNB REMACO

Turbo-Generator Services Division

"I'm recognize with his technical knowledge and experience of turbo-generator. He is recognize with his skill, knowledge and experience and he capable to adding value to any company".

Mior Amir Hamzah

Senior Engineer at GE Vernova

Generator ITR Engineering

"It is pleasure for me to recommend Abdul Gaffa Khan for a position in any related company with his skill set. He has a good technical knowledge with good attitude towards customer, colleague and superior. Always a reliable when needed and willingness to support the team during the difficult period".

Lai Chin Kit

Head of Electrical Maintenance at

SENOKO Power Station, Singapore

"Gaffa is a team player that can work well with others to complete the job on time and with high quality. He can keep a cool head even under pressure to push through the necessary details needed to achieve the target. He is a qualified Mechanical Field TA that is valuable for the organization".